What we do

Building codes require the owner to employ the necessary special / deputy construction inspector. It allows the owner to employ the special / deputy construction inspector directly or through out one of the following:

The Architect or Engineering firm in charge of the design of the structure; the geologic or soils engineering firm providing the technical data for the project.

Definition of Deputy Building Inspector.

A Deputy Inspector has demonstrated the knowledge, skill and ability to provide Bldg. special inspection for specific construction operations. The Deputy Building Inspector is employed by the owner either directly or indirectly through an authorized agent but is responsible to the architect, engineer or soils/geological firm who has prepared plans, specifications or technical details requiring special inspection.

Deputy Inspection Services

To accommodate the increasing needs in the construction industry, Deputy Inspection Services offers services in the following disciplines:

G.P.R. or Ground Penetrating Radar

Ground Penetrating Radar (G.P.R.) is a safe, extremely fast, and accurate tool we use to locate materials within a concrete structure. The emission of electromagnetic energy travels through the concrete and is returned to the receiver where it determines whether the objects is steel, plastics, concrete etc. These determinations are based on the dielectric constant and the intensity of signal returned.

Concrete & Masonry Coring

Special Deputy inspection offers concrete and Masonry coring. We utilize G.P.R. or Ground Penetrating Radar to insure accurate drilling and avoiding electrical conduits, or obstructions. Our staff is trained and experienced and only utilizes the highest quality tools and accessories.

Drill In Anchors

Special/deputy inspection is required for all drill-in anchors; which include the following: expansion anchors, chemical (adhesive) and grouted anchors, and un-reinforced masonry (URM) anchors. The inspection is required to ensure that all materials and installation procedure comply with recognized standards and contract documents.

Masonry Construction

Special Deputy inspection for masonry is required for the preparation of any pre construction masonry prisms, mortar field testing when needed, during the placement of all masonry units and reinforcing steel, prior to enclosing clean outs, and during all grouting operations to obtain the necessary testing samples.

Structural Wood

Special inspection is required during field gluing operations of elements of the main windforce-resisting system and for nailing, bolting, anchoring and other fastening of elements; such as wood shear walls, wood diaphragms, drag struts, braces and hold-downs.

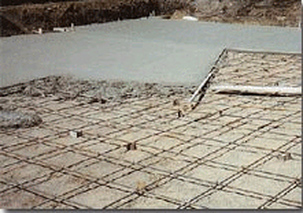

Reinforced Steel/Bolts

Special deputy inspection is required when for the placement of reinforcing steel, Hex Head Bolt, J-Bolt, Headed Stud bolts and all reinforced steel, prestessing tendons, within concrete placements that exceeds 2500 p.s.i. for compliance with approved plans, building code and contract documents.

Pre-stressed Concrete

Special/deputy inspection of pre-stress / post-tension concrete is required to verify reinforced steel, pre-stressing tendon, application of stressing forces and grouting of bonded pre-stressing tendons in the seismic-force resisting system.

Steel Construction

Special deputy inspection is required for the welding of any member or connection that is designed to resist loads and forces required by code, during the field welding of special moment-resisting steel frames and during the welding of reinforcing steel. Inspection of any welding performed at unapproved fab shop that is designed to resist loads and forces required by code, may also be required by approved documents.

NDT / UT MT/ RT

Special deputy inspection and nondestructive testing of structural steel elements in buildings, structures, and portions thereof shall be in accordance with the quality assurance requirements of AISC 341. These provisions shall apply to steel in the seismic force-resisting systems of buildings, structures assigned to seismic design Category D, E or F for compliance with approved requirements.

High-Strength Bolting HSB

High-Strength Bolting: Special deputy inspection for high strength bolting is required during installation and tightening of bolts A325 and A490 is in accordance with recognized standards.

Sprayed Fire-Resistant Materials

Special inspection and tests of Sprayed fire-resistant materials applied to floor, roof, wall assemblies and structural members shall be performed to ensure fire-resistance design as designated in the approved construction documents and with Technical Manual 12-A & Technical manual 12-B.

Shotcrete / Gunite

Special inspection maybe required for the placement of reinforcing steel, during shotcrete application and the assembly and shooting of pre-construction test panels, if required by contract documents. Shotcrete is defined as pneumatically projected concrete at a high velocity onto a surface.

Pull Test / Torque Testing

Deputy inspection to apply a tension test load is required for post installed drilled-in expansion or chemical-type anchors or reinforcing steel dowels in concrete or masonry by DSA and OSHPD. This procedure, could be used if approved by the designer or/and the building department jurisdiction, as an alternative method of compliance for installations performed without special inspection at the time for installation.

We also provide services for:

- Scanning using Ground Penetrating Radar (GPR)

- Concrete Voids and Utility Location

- Thickness scanning for walls & other structural Elements

- Suspended Ceiling Inspections / T-Bar Systems